|

|

|

Top Stories

Update 2021/6/9

Biochar

HAVING SUCCESSFULLY DEVELOPED A TECHNOLOGY TO CLEAN UP WASTE STREAMS,

START-UP SIMEKEN INC NOW LOOKS TO CONTAMINATED WATER CLEANUP

By Suzanne Forcese

In 2018, a handful of engineers and entrepreneurs in British Columbia, Canada, seized upon an opportunity to build on their green goals. A proven waste management technology in California that produced biochar came across their radar and aligned with the group’s mission.

It all started with a dream to make a difference when the late Jim Sipprelle wanted to solve some pretty hefty environmental issues – waste streams, the high cost of energy, and green-house gases. He wanted to do it green, clean, and cost effectively.

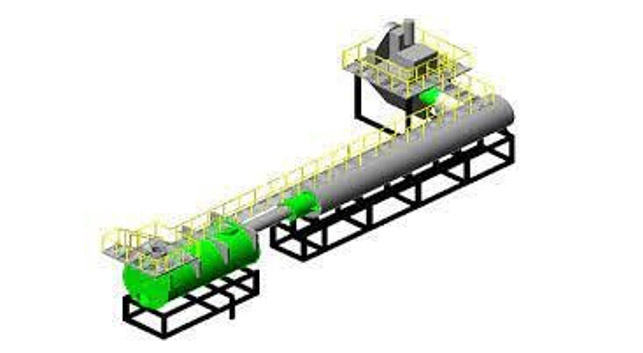

With a solid engineering team Simeken Inc. was born with the creation of a uniquely shaped Retort Oven that handles a wide variety of waste streams. All without moving parts.

The added bonus – there is only one output. Pure carbon, also known as biochar.

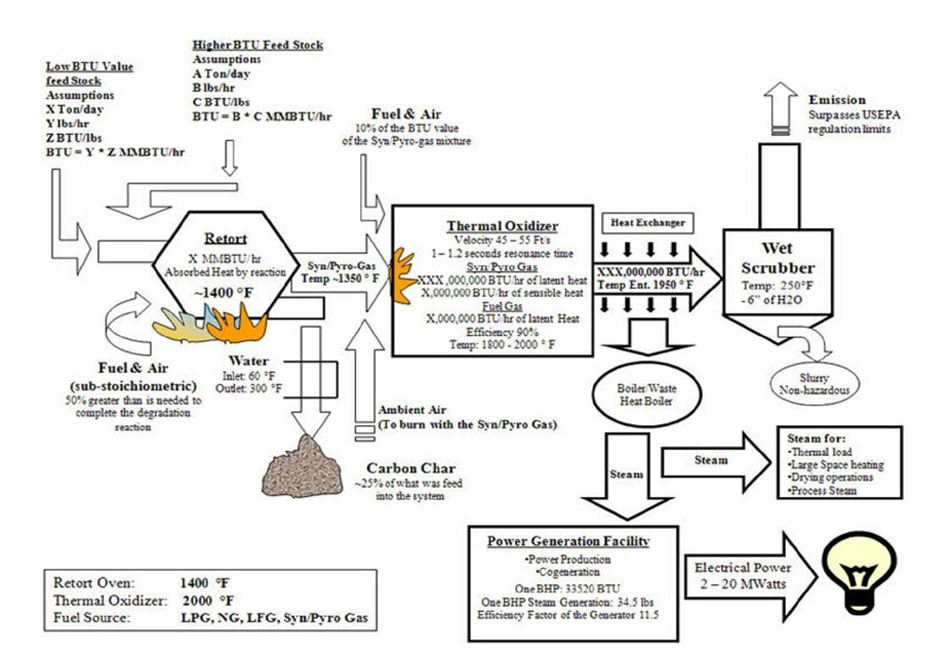

The Simeken PRO™ (Pyrolysis Recovery Oven) System mitigates global warming by converting waste into green and clean energy. There is only one output – pure carbon or BIOCHAR which

can be used as a natural fertilizer and also as a means to manage ground water contaminant

When Jim Sipprelle passed away, this proven technology sat idle for a few years. But the dream lives on with the new Canadian ownership.

WATERTODAY had the pleasure of speaking with Rod Pare.

“We have been involved with and completed many alternative green energy projects such as hydrogen fuel cells, digesters, PCBs as well as complementary tech. We saw there was a future with managing municipal solid waste (MSW) with the

Simeken Pro, so acquiring the Company was the next step.”

The Pyrolysis Recovery Oven is a high-temperature thermal device that can reduce waste, provide recycled by-products and create heat for the generation of clean electricity and renewable fuels with its advanced waste treatment technology. The system operates in an oxygen-restricted environment to help eliminate air pollution.

“Our patented technology includes a shredding and conveying system, the PRO™ Retort

Oven, a thermal oxidizer, a wet scrubber and a char output system. Basically, we feed product into an Oxygen free environment that is broken down into three parts – biochar, oil,

and gas,” Rod Pare told WT

Virtually any waste stream can be fed into the feed systems.

- Agriculture

- Tires

- Municipal solid waste

- Construction & demolition debris

- Food industry waste

- Plastics industry waste

- Wood industry waste

- Pulp & Paper industry waste

- Sewage sludge medical waste

- Contaminated soils

- Biomass

- Hazardous waste

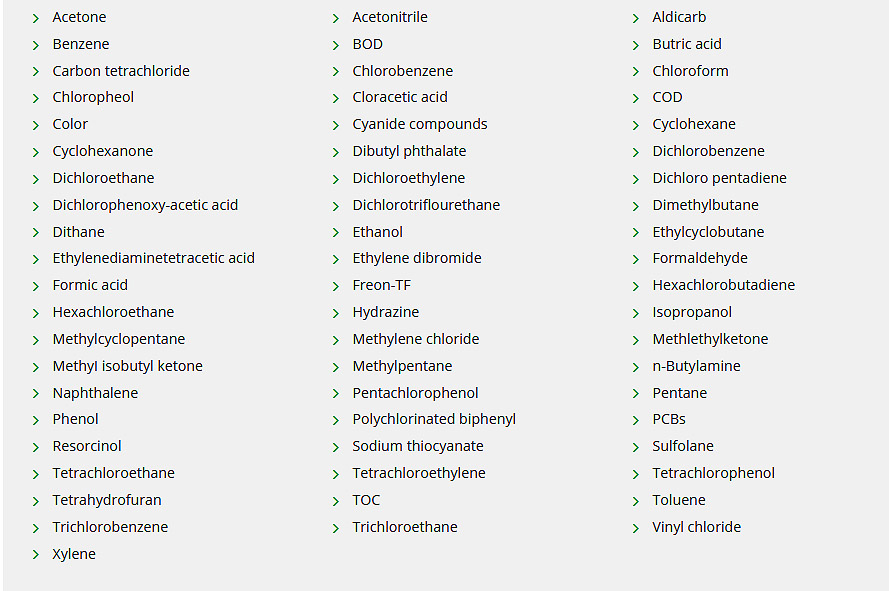

Successfully destroyed contaminants in the demonstration plant in Bakersfield, California include:

The team is now ready to start testing and characterizing the by-products that will be produced – solid (biochar), liquid (bio-oil) and gas (syngas).

“Our long-term goal is to produce biochar as well as convert (upgrade) our vaporized bio-oil and syngas into either RNG or green hydrogen through the use of our technologies.”

As a soil amendment, Biochar ameliorates soil texture and releases oligo-elements (natural fertilizer) slowly, increasing crop yield. It aids in nutrient retention and promotes healthy root growth, while minimizing pathogens that cause disease and bugs.

Biochar also sequesters carbon.

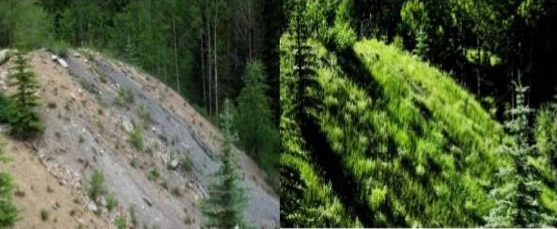

Mine Tailings Google Image

Biochar can prevent contaminants present in the soil of abandoned mines from leaching into local water supplies by sequestering heavy metals and acids. This can help in quick reclamation of mines at lesser cost.

Hope Mountain Mine near Aspen, Colorado

On the left 100-year-old mine tailings contaminated with heavy metals. On the right revegetated with biochar in one year.

The leached soil can now support plant growth due to the improved soil fertility, increased infiltration and reduced erosion

“We want to utilize and tailor our biochar to mitigate many of our groundwater contaminants that are polluting our rivers, streams, lakes and surrounding wetlands,” Pare states.

There is a growing awareness of “emerging contaminants” that have a chronic or long-term detrimental impact on the environment, aquatic life, wildlife and humans.

These include micro-plastics, contaminants from nano-technology such as nanofibres that penetrate cell walls and immobilize bacteria in the environment.

A group of these chemicals have been found to affect the hormone and reproductive systems of aquatic organisms, wildlife...

And humans.

Hormone disruptors commonly used in medications, birth-control hormones, cleaning chemicals, fragrances, personal care products, anti-bacterial hand wash and various other organic and inorganic pollutants are released into municipal sewers either as a result of direct disposal or indirect release as part of human waste discharged every time a toilet is flushed.

Over 800 chemicals have been found to exhibit or cause hormone and reproductive disruption and DNA damage in aquatic and wild life, and humans.

In Canada there are presently no standards for the treatment/removal of Endocrine Disrupting Chemicals (EDCs) from wastewater or acceptable levels in receiving environments.

Biochar offers the potential to effectively remove EDCs from reclaimed water, can be made locally from available waste-carbon feedstocks, is cheaper that activated charcoal.

“It also has the potential to destroy all organic contaminants including EDCs.” “Safe drinking water should be our number one goal and we feel biochar can be a big contributor in achieving this,” Pare told WT while reflecting on his raison d’etre -- “I want to exit this planet knowing I have made a difference.”

suzanne.f@watertoday.ca

|

|

|

Have a question? Give us a call 613-501-0175

All rights reserved 2026 - WATERTODAY - This material may not be reproduced in whole or in part and may not be distributed,

publicly performed, proxy cached or otherwise used, except with express permission.

|

| |