|

|

|

Features

Update 2020/12/17

Renewable Energy

CORVUS ENERGY IS TURNING THE TIDE FOR THE MARINE SECTOR

By Suzanne Forcese

Shipping accounts for 2.2% of the world’s greenhouse gas emissions.

Around the globe, from ferries, freighters and cruise ships to submarines, tug-boats and the vessels that serve offshore oil and gas rigs, Canada’s Corvus Energy is reducing carbon emissions by 20-30% for hybrid vessels and 90% for electric vessels.

Zero-emission ferries, like this all-electric ferry in Denmark, use Corvus Energy’s ESS (Electric Storage Systems) for over 60 similar short-distance hybrid and all-electric car ferries globally –

more than all other providers of battery-based ESS combined.

Corvus first came to the marine market in 2010 with a lithium-ion battery-based hybrid power system for tugboats. Now the company’s clean technology is found all over the world. Using battery systems on board is increasingly becoming an attractive solution in many shipping segments.

WATERTODAY had the pleasure of speaking with Sean Puchalski, Executive Vice President, Strategy & Business Planning of Corvus Energy’s Richmond, B.C., base.

“Energy Storage Systems (ESS) are fairly complex when we compare them to the ‘old school’ acid batteries that most people think of,” Puchalski tells us. “The lithium ion will degrade if not managed properly. Our systems are completely computer controlled with special thermal management features.”

In B.C. Puchalski adds, “This is the complete green solution for ferries.”

The Corvus Orca Energy represented a shift in the Maritime Industry when launched in 2016 Ideal for applications that are in need of both energy and a high amount of power, the Orca is used in Ferries,

Cruise Ships, Ro/Ro-Ro/Pax, Yachts, Offshore vessels (Rigs, Tugs, Fishing Vessels), Merchant Vessels (port cranes, shore charging, fish farms)

Cruise ships and ferries are the “bread-and-butter” of the Company Puchalski goes on to say. “By removing a diesel engines, a 20 minute ferry crossing can be completely electrified. And for the larger ships the battery reduces fuel consumption by 20-30% in a hybrid.”

As for cruise ships, “There are only about half a dozen things that can be done with a battery on ships. However, the important feature is in understanding load management.”

Off-shore, cruise ships are required to stay one metre away from structures, regardless of wind, current. “There’s a lot of pulsing in that dynamic positioning. The battery allows the ship to be fuel-free in port.”

As far as drilling rigs are concerned, energy can be regenerated. “The old-fashioned way, Puchalski continues, “is to burn off that spinning energy. It is completely wasted. Now we can collect it for regenerative braking, much like an electric car does.”

Tugs usually work around a home base port or fish farm so it is important to be vigilant regarding pollution and noise.

The Corvus Orca Energy represented a shift in the Maritime Industry when launched in 2016 Ideal for applications that are in need of both energy and a high amount of power, the Orca is used in Ferries, Cruise Ships, Ro/Ro-Ro/Pax, Yachts, Offshore vessels (Rigs, Tugs, Fishing Vessels), Merchant Vessels (port cranes, shore charging, fish farms)

One of the first hybrid tugs delivered with a Corvus ESS

“Anything that has engines for maximum workload that isn’t working at max all the time can reap huge efficiency gains with Corvus ESS,” Puchalski sums up.

Puchalski adds that “we got into the subsea segment quite by accident when we won an engineering project for Boeing’s Echo Voyager, which led us to research in the North Sea. We offer a reliable endurance system that’s packed together.

“Research vessels can work autonomously, at enormous cost savings instead of paying for a ship that is tethered and running constantly.”

One of the world’s most advanced offshore construction vessels, North Sea Giant is the first vessel where batteries are part of the DP3 power management system. ESS provides spinning reserve power to all parts of the ship instead of using diesel gensets contributing to substantial reductions in costs and emissions.

Through the entire value chain from design and procurement, through production and operation of installed maritime battery systems, re-use and re-cycling is an important part of the Corvus strategy.

“99.9% of our batteries weight can be recycled. When a lithium-ion battery has served onboard a ship for its intended use and lifetime, the remaining capacity can be used for other purposes -- such as making energy to fuel a plant. Also, the demand for lithium and cobalt are high. “We can extract these from infrastructures no longer in use.”

Corvus Energy is primarily headquartered in Bergen, Norway. Puchalski says that Norway has been the largest customer. Tapping export markets has been critical to the company’s success. “We are however now seeing an uptick in Canadian interest.”

The advantages of the Richmond base lie in the global respect for Canadian technology, and the pool of high calibre engineering talent. “We are also an important international port.”

The company is now moving forward with its Canadian operations in an expansion at the Richmond, B.C. facility and increased manufacturing capacity.

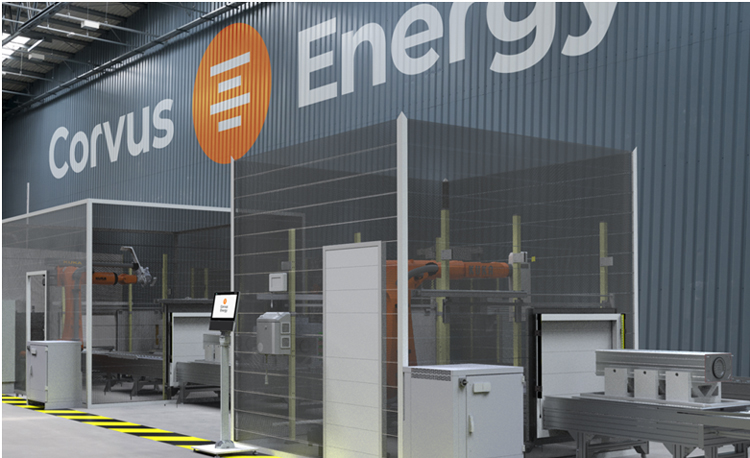

The illustration shows part of the new production line to

be installed in the Corvus Energy plant in Richmond, B.C.

The state-of-the-art production equipment will be based upon the same flexible robotic technology used in the battery factory in Bergen, Norway.

The Canadian facility which is expected to be completed in 2021 will be producing the newest multi-megawatt hour ESS, called the Blue Whale (introduced in June 2020). It is expected to be the cornerstone of Corvus’ growth in coming years.

“The market for these enormous battery systems will increase rapidly as cruise ships, large ferries and merchant vessels strive for zero-emissions operations.”

The Canadian plant will focus on the North American and Asian markets. “For us that’s about one-third of our business, whereas Europe is two-thirds.”

Moving forward, Puchalski sums up the Company’s vision –

“We are powering a clean future for all segments of the Maritime Industry by combining our maritime DNA with the most advanced lithium power technology in our state-of-the-art Energy Storage Systems.”

suzanne.f@watertoday.ca

|

|

|

Have a question? Give us a call 613-501-0175

All rights reserved 2026 - WATERTODAY - This material may not be reproduced in whole or in part and may not be distributed,

publicly performed, proxy cached or otherwise used, except with express permission.

|

| |