Features

Update 2021/11/1

Desalination

Manure To Fresh Water – Northeastern University Professor leads Research in water desalination going from “Nano” to “Bio”

By Suzanne Forcese

“I’m not saying I am abandoning nano-technology, but when Nature provides a low cost, efficient, environmentally superior solution, why not go with the natural material.” -- Yi Zheng, Professor Northeastern University, Boston; Director of Nano Technology Laboratory; NASA Research Scientist-- in a conversation with WATERTODAY.

The latest research (led by Dr. Yi Zheng) coming out of the Nano Energy Laboratory in Boston’s Northeastern University is purifying salt and brackish water – free of contaminants, bacteria and viruses.

The result -- water that exceeds drinking water standards set by the U.S. Environmental Protection Agency.

The simplicity of the revolutionary process is time and cost efficient, sustainable, recyclable, and environmentally supportive.

All this is possible with biomass- derived composites and sunlight.

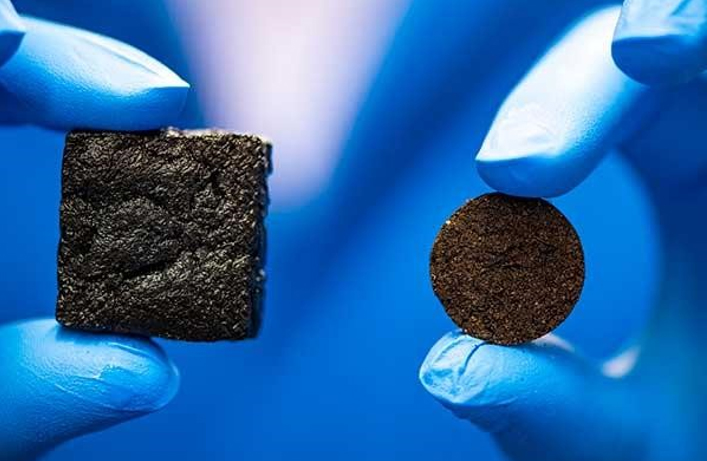

Yi Zheng holds a sample desalination filter made of cow manure (left) and one made of hornet nests in the Nano Technology Lab at Northeastern University. Photo Alyssa Stone

According to recent UNICEF statistics, 1.42 billion people on Earth live in areas of high or extremely high water-vulnerability. That’s one-quarter of the Earth’s population.

In the face of exponentially growing population and recurring droughts in many regions of the world – including Canada and the United States -- desalination has been acknowledged as a technology that can help alleviate the identified stress on water resources while also protecting natural habitats and environmental flows.

However, desalination is an energy-demanding process commonly powered by nonconventional energy sources which are unsustainable. Traditionally, desalination processes, are mainly based on thermal and membrane technologies including reverse osmosis for example.

Recently, advances in nanoscale science and engineering have been gaining attention as a means of water purification.

“Water desalination is not a new topic,” Zheng tells us. “But all processes are complex, consume electricity, are labor intensive and are also very expensive.

“As far as nano technologies – these materials do not exist in Nature. Materials used in these processes have to be fabricated. Many researchers have accomplished this. But the expensive equipment and time involved are not sustainable.

“For example, the use of a freeze drier over several days creates only a small amount of nano-materials.”

“My goal is to avoid nanotechnology by taking advantage of clean solar energy and natural biomass – it’s all free.”

The natural materials Zheng and his team have used to desalinate seawater in sunlight include tree leaves, cuttlefish ink, crab and lobster shells, hornet nests, and office paper waste.

Zheng’s research has received acclaim in the science journals, Cell Reports Physical Science, ACS Applied Materials & Interfaces, ACS Omega, Nanoscale, and the Journal of Materials Chemistry A.

His solar energy harvesting designs have also captured the attention of NASA with his recent appointment as NASA research scientist.

Now the latest breakthrough discovery is that manure provides a free and naturally abundant source for natural carbon that can be used in sunlight to outperform all current methods of desalination.

“It’s really such a simple process. It does not require infrastructure, electricity, expensive chemicals or training making it advantageous for off-grid communities or communities in underdeveloped countries.”

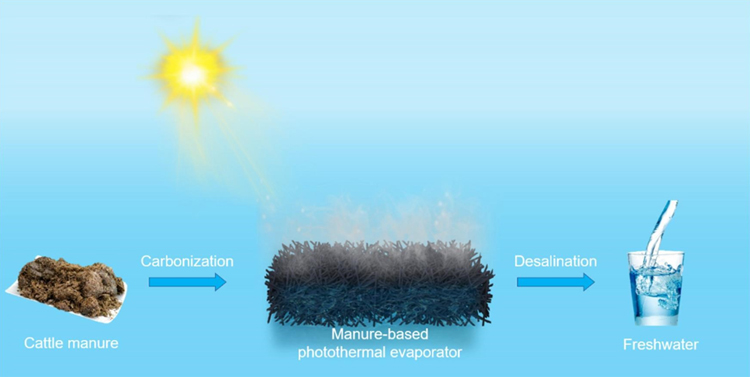

A carbonized fibrous foam derived from cattle manure facilitates water and salt transportation by means of solar evaporation.

The process of manure-based foam to fresh water in sunlight produces 5.3 litres per hour per square metre -- a substantial increase from the highest recorded nano-structured evaporators which produce 2.5 litres per hour. “The results surprised us,” Zheng told WT

The Aha! Moment

Like many breakthrough discoveries, there is a certain amount of chance and timing involved.

“It was over a year ago,” Zheng says. “We were all sent home because of the pandemic. I couldn’t go to my lab.”

With the extra time on his hands, Zheng took a trip to a local dairy farm to purchase some products.

“While I was waiting for the farmer to gather my products, I happened to notice that not only were there a lot of horses and cows on the farm but there was a lot of manure. I mean it was everywhere!

“And I got to thinking...cows are vegetarians...the manure is a result of pure digestion...why not harvest the carbon and fabricate my own nano materials...”

The farmer was more than happy to provide Zheng with a free bucket of manure which otherwise would be an expensive undertaking to remove from his land.

And the rest is history.

A Solution to A Global Crisis

“I have always wanted solutions to my global goals of reducing carbon emissions, mitigating water crises, harvesting solar power, and empowering communities. I have always wanted to improve on what we already know.

“Coming from a third world country myself, I am very aware of the stressors and hardships of these countries and the similar struggles of off-grid communities in Canada and the United States.”

With those goals as his beacon, Zheng set about working through the manure.

The first step was heat. “Our ovens are capable of 1700°Celsius but we only needed to go as high as 500°Celsius to kill all the bacteria and viruses.

“After that heating, only the natural carbon remains. The resulting material (a black foam carbon filter) is extremely porous and water absorbent. We simply float that on the surface of the water. In sunlight, the water beneath the black foam turns to steam and passes through it.”

Zheng has created a patent-pending chamber that turns the raw biomass into a black foam.

Using sunlight only – no electricity – the chamber converts salt and brackish water into drinking water in as little as 3 or 4 days.

“Ocean water is easily absorbed by the manure-based foam filter. In the sunlight the water turns to steam, passes through the filter, and then is condensed back to water under a dome.”

What’s Next?

“We are studying durability.”

So far, the team has discovered that the foam filter is good for up to one month. The carbonized manure is completely natural. No chemicals or electricity are required.

“Carbonized manure can convert 98% of sunlight into heat. We have also demonstrated that the prototype exhibits rapid water pumping and efficient salt rejection.”

Another advantage is that the material is recyclable. “All we have to do is return it to the oven to carbonize it again.”

“All materials are totally natural and sustainable which means that small communities off-grid can set up the system. All that is required is some hydraulic equipment to make carbonized manure and collecting the raw materials.

“This could mean equitable access to drinking water around the world.” Zheng’s vision is to commercialize the system as quickly as possible.

With that goalpost in mind, Zheng has founded a spin-off company, Planck Energies.

“Carbon neutral technology is a hot area right now. People are demanding environmentally friendly systems. We cannot forget Nature.”

suzanne.f@watertoday.ca

|