|

|

|

Features

Update 2021/7/13

WTech

NICHE START-UP NORSEPOWER REDUCES ENVIRONMENTAL IMPACT OF SHIPPING WITH ROTOR SAIL TECHNOLOGY

By Suzanne Forcese

A manufacturer of auxiliary rotor sails, Norsepower Oy Ltd., has re-engineered the 100-year-old concept of wind, drag, and lift to bring sailing back to shipping.

The same principle that keeps airplanes aloft is moving ships forward using rotor sails that are mounted on ships’ decks to give thrust when the wind blows, making shiping greener by reducing carbon emissions.

Founded in 2012, Norsepower Oy Ltd, headquartered in Helsinki, Finland, a manufacturer of auxiliary rotor sails that are mounted on ships' decks to give thrust when the wind blows.

Video: Bringing Sailing Back to Shipping

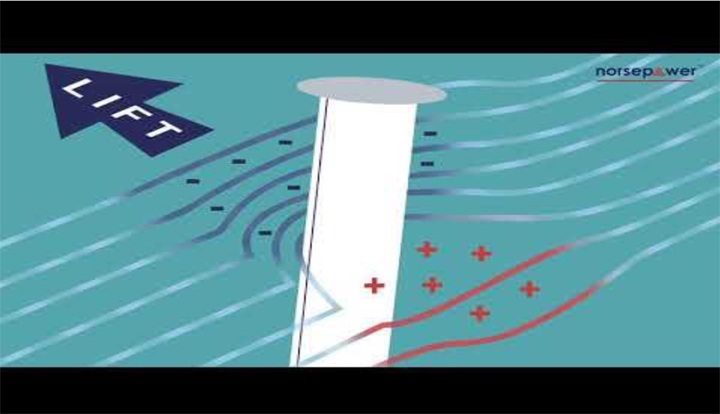

The Norsepower Rotor Sail Solution is a modernized version of the Flettner Rotor -- A spinning cylinder that uses the Magnus effect to harness wind energy to propel a ship. When wind conditions are favourable—as often is the case in international ocean trade routes -- the aerodynamics of the air pressure difference surrounding the cylinder creates thrust that is transferred to the ship. Photo Norsepower

WATERTODAY had the pleasure of interviewing Tuomas Riski, CEO of Norsepower OY.

CEO Tuomas Riski.

In 2012, with a business idea to combine clean-tech and engineering (his two passions) Riski moved from a career in Finland’s IT sector to found Norsepower OY.

“I worked with the renowned naval architect, Prof H.C. Kai Levander from Finland to bring a modernized Flettner rotor to the market. From this union of well-known principles and innovation Rotor Sail Technology, Norsepower was born.”

“In 2012, when it was clear that global environmental challenges were ever increasing, I started to look for a new clean-tech concept that would have a big impact on global CO2 emissions,” Riski tells us.

The International Maritime Organization (IMO) has set targets for 40% reduction of CO2 emissions by 2030 and 70% by 2050, compared with 2008 levels. These targets set alongside a set of new indices that will become mandatory in 2030 – The Energy Efficiency Ship Index (EESI) and the Carbon Intensity Index (CII).

“With these measures in place, there are broader calls for shipping to raise their ambitions and reach net zero by 2050.”

Recognizing the need to decarbonize the shipping industry, Norsepower was born.

“We are committed to bringing sailing back to shipping, reducing fuel consumption, costs, and emissions.

The optimal number and size of Norsepower Rotor Sails are determined by the size, speed, and operating profile of the vessel. Data from vessels where Rotor Sails are deployed – independently verified by a number of monitoring and verification companies – show up to 25% emissions and fuel savings annually.

Shown here Norsepower’s latest installation—5 tilting rotor sails-- on the Very Large Ore Carrier (VLOC), chartered by Vale the Brazilian Ore Company. It is estimated the Rotor Technology will result in an annual efficiency gain of 8% and a carbon emissions reduction of up to 3400 tons per year

Photo Norsepower

Norsepower Sails are based on the Flettner Rotor which was originally invented by Finnish inventor and architect Sigurd Savonius and German engineer Anton Flettner in the 1920’s.

“The basic engineering solution had a limited degree of sophistication, but Norsepower created various new improvements for which several patents have been granted, “ Riski told WT.

Video: Rotor Sail explained

When wind conditions are favourable, the Rotor Sails allow the main engines to be throttled back, saving fuel and reducing emissions while providing the power needed to maintain speed and voyage time. A variable electric drive system, which is powered by the ship’s low voltage network, is used for rotating the Rotor Sail.

The Norsepower Rotor Sail technology is around ten times more efficient than a conventional sail, because more lift is produced with a much smaller sail area. Due to its simplicity, it requires no reefing or crew attention when in operation. It is “push-button wind propulsion” from the bridge.

“We acknowledge that one size does not fit all,” Riski continues. “We have five different model to ensure optimal dimensions for different vessel types.”

Rotor Sails can also be tilted by using hydraulic cylinders.

“The tilting rotor sail has opened up markets for vessels navigating height restricted routes.”

Sea Cargo Connector showcasing vessels that have to negotiate height restricted routes Photo Geir Bernsten

Video: SC Connector tilting Rotor Sails animation

“Our continuous incremental design improvements mean that we have improved Rotor Sail efficiency to reach average savings of up to 25%.

Norsepower Rotor Sails are suited to a wide range of vessels including ferries, tankers, Ro-Ro's, general cargo ships, LNG carriers and bulk carriers as well as cruise, and RoPax vessels. Norsepower Rotor Sail technology is available and easily installable as a retrofit today on current fleets.

“It is important to recognize that retrofitting vessels with Rotor Sails provides more than just meeting EESI compliance targets. Investors, financiers and cargo owners have introduced a number of ‘demand side’ measures that are forcing shipowners and operators to invest in reducing their fuel and emissions as they in turn come under consumer pressure.”

In the push for more Environmental and Social Governance (ESG), Riski leaves us with this thought --

“Wind power will make a critical contribution to achieving decarbonization goals. There is no doubt that wind propulsion in shipping is a market that will grow significantly over the next few years. It is a freely available resource for us to utilize.”

Bringing sailing back to shipping.

suzanne.f@watertoday.ca

|

|

|

Have a question? Give us a call 613-501-0175

All rights reserved 2026 - WATERTODAY - This material may not be reproduced in whole or in part and may not be distributed,

publicly performed, proxy cached or otherwise used, except with express permission.

|

| |