Features

Update 2023/2/22

Space Food

brought to you in part by

Cultivating Chlorella and Regenerating CO2 in Space

A University of Waterloo Chemical Engineering team develops a combined food growth and environmental regeneration device

By Suzanne Forcese

“We have developed a simple system for producing protein in space, which also happens to be relatively inexpensive. This is great for growing algae on Earth too because algae can be used to make biofuels and plastics in a renewable way - Dr. Valerie Ward, Assistant Professor, University of Waterloo

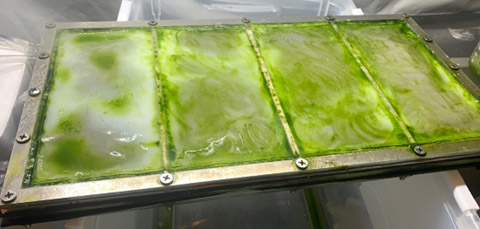

Professor Valerie Ward and Professor Nasser Mohieddin Abukhdeir teamed up with students to develop a hydrogel photobioreactor where they are growing microalgae called Chlorella.

Researchers constructed a metallic frame for the algae that uses minimal water and energy through innovative design. In this photobioreactor, water is diffused through hydrogel. The algae have the consistency of play-doh and can be freeze-dried to be used in smoothies, pasta, or soup.

WT: Congratulations on advancing to the semi-finals in the Deep Space Food Challenge! What aspect of the Challenge inspired your team to enter?

Abukhdeir: Regarding growing food in Space, or here on Earth, controlled-environment agriculture is vital for increasing the sustainability of food production. It is especially important in Space as the habitat is closed. This requires increased coupling of food production with life support to minimize the reliance on external supplies.

WT: Dr. Abukhdeir, you are the founding member of the Computational Multiphysics Research Group. How does your research complement Dr. Ward’s? Why was it a good fit for both of you in this challenge?

Abukhdeir: Computational Multiphysics refers to the study of coupled physical and chemical processes using computational methods.

Dr. Ward’s background in microbiology and biochemical engineering is complementary to mine because the proof-of-concept device is a complex piece of technology that involves a unique combination of physical geometry, chemical reactions, and biological growth that must work together to produce the food product.

We also complement each other in this work because we are working on mathematical models both for the photobioreactor itself and the closed life support system in which it operates. I can lend my expertise to the model aspect while Dr. Ward can ensure and test the validity of the model.

The use of models to predict performance is an important part of engineering design, especially for mission-critical systems.

WT: Tell us about the Team and their areas of expertise.

Abukhdeir: As a biochemical engineer and microbiologist, Dr. Ward works on engineering microalgae systems as a sustainable source of chemicals and materials to replace less environmentally sustainable products. She is an expert in microalgae cultivation and growth media formulation, and she researches the production of food or pharmaceutical products. She is also well-versed in the safety aspects of manufacturing biological systems.

I use computational engineering tools, along with physicochemical models, to predict the performance of diverse types of chemical process equipment both for design improvement and “clean sheet” design. This is a safer and more cost-effective way of engineering design than exclusively relying on experimentation.

Craig Harrison is currently a fourth-year chemical engineering student at UW. He worked on developing our smallest-scale prototype

Nicholas Rasmussen is currently working on a master's degree based on this project. He has hands-on experience with equipment sizing, valve and instrument selection, and P &ID and CAD development.

WT: Why did you focus on algae-based food?

Abukhdeir: Dr.Ward explains that depending on how they are grown, algae powders can be high in protein as well as some of the nutrients that astronauts would normally get from animal protein sources like Vitamin B12 and iron.

It also has a good amino acid profile that covers the essential amino acids that humans require in their diets. They also grow much faster than plants and the entire cell is edible unlike plants that make roots, stems, and leaves. In a place where you need to be as efficient as possible – like Space—algae meet that requirement.

WT: Your entry in the Challenge, “Hydrogel Photobioreactors for Cultivation of Food and Life Support”, has been described as a type of food growth and environment regeneration device. Can you unpack that description for our viewers, please?

Abukhdeir: Our proposed technology is a dual-use microalgae growth system which addressed significant issues associated with traditional microalgae photobioreactors, similar to those tested in the ISS in 2019.

The system provides both CO2/O2 conversion, to supplement primary life support systems, while simultaneously providing a nutritious food supplement for the crew.

Microalgae is a single-celled photosynthetic organisms capable of growing much more quickly than land crops. It has a much higher growth rate and higher photosynthetic efficiency.

The main challenge is that microalgae grown directly in water require complex air dispersal devices, use an excessive amount of water in their growth, and require water to be removed prior to consumption.

The proposed design, referred to as the algae rack, innovates traditional designs by segregating the liquid (water and macronutrients) from the air by growing algae on a solid hydrogel support, within which liquid nutrients are contained and transferred.

This minimizing water usage limits water supply to that which diffuses through the hydrogel, thus removing the need for complex air/liquid and algae/liquid separation technology.

Harvesting is a simplified mechanical method (a squeegee!).

The use of fibre optics and traditional LCD backlight diffusers of the proposed technology achieves production efficiencies per unit volume greater than traditional photobioreactors and hydroponics systems.

The design's optimal efficiency is ideal for extreme terrestrial climates as well as space exploration and colonization.

WT: How is a hydrogel photobioreactor different from a photobioreactor?

Abukhdeir: A photobioreactor is any system which supports biological growth that involves light.

A hydrogel photobioreactor uses a solid support for algae growth (hydrogel) which separates the liquid nutrient flow from the growing microalgae, addressing one of the key issues associated with traditional mixed designs.

Hydrogels are hydrophilic. Thus, there is a negligible loss of water from the nutrient delivery system into the environment.

Growth on the solid support also simplifies harvesting as it can be squeezed directly from the surface of each hydrogel model.

WT: How does your system provide the needs for plant growth – sunlight and water?

Abukhdeir: It provides water, macronutrients (dissolved in water), CO2 from the environmental air, and light from LED lighting specially designed for this purpose to only emit photosynthetically active radiation (PAR)

WT: Moving forward, what are the next steps for your team in the Challenge? How do you envision the astronauts maintaining the system?

Abukhdeir: Once set up, the algae rack should require little maintenance apart from harvesting the algae every few days. The system would require only a few hours of training. Harvesting can be done while the unit is operating and should take only a few minutes.

For long-term missions, the system is meant to provide a nutritious high-protein microalgae food supplement (380g/day) while simultaneously regenerating O2 from CO2 corresponding to 4 humans’ consumption/emissions per day.

WT: How can your system expand opportunities for Earth?

Abukhdeir: We think the algae stack system can also be used terrestrially, for similar purposes.

It uses extraordinarily little water compared to the algae/food supplement it produces, while simultaneously regenerating O2 and CO2.

While CO2 is quite plentiful on Earth, there are many environments where water usage and exchanging “fresh” air in the local environment (extremely hot and cold climates) is resource intensive. Our technology could be deployed terrestrially for food production to minimize inputs, resources, and space while maximizing efficiency compared to traditional hydroponics systems.

WT: Any last thoughts you would like to share with our viewers?

Abukhdeir: While there are some serious pressing issues to solve on Earth, sometimes competitions like this can spur innovation in new directions outside of the intended purpose. For example, our device can be used on Earth to solve some problems right here like CO2 sequestration and wastewater treatment.

|